ARGES pH Sensor

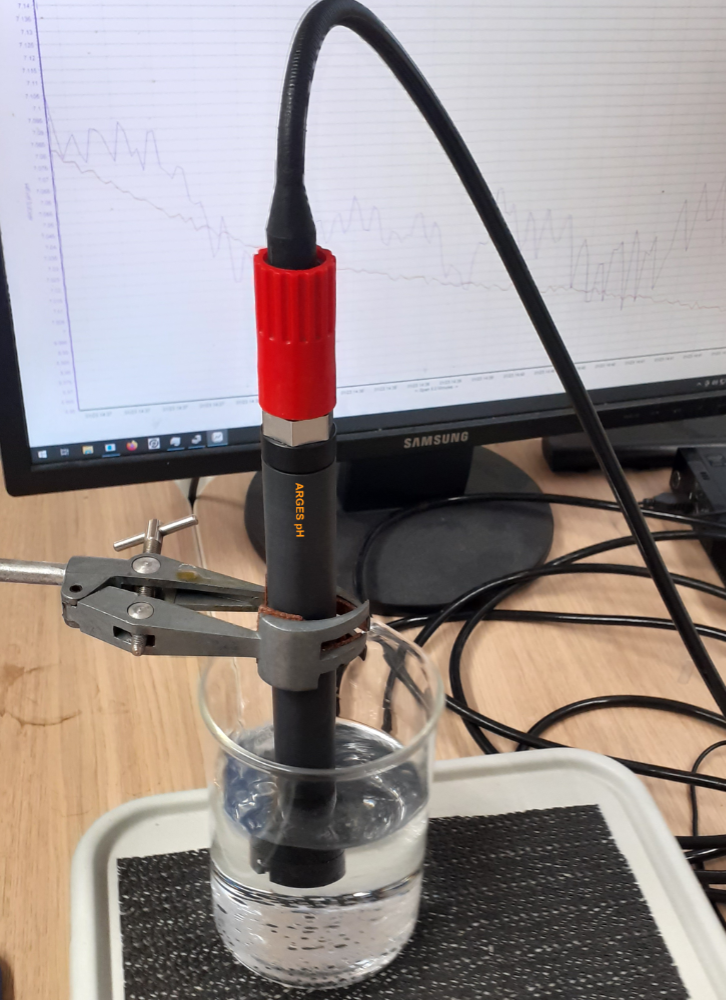

The Intelligent ARGES pH Sensor By Keynes Controls is a submersible sensor that has been designed to simplify the acquisition of water quality measurement parameters into any platform that supports real-time reporting, data logging operations.

The ARGES pH Sensor by Keynes Controls can be used as a stand-alone sensor, or as part of a multi-parameter sensor array. All of the ARGES range of chemical sensors can be combined with the other Keynes Controls sensor interfaces using the same common User interface.

The ARGES pH Sensor by Keynes Controls supports SDI12, RS485 and MODBUS digital networks.

pH in water sources

pH is a measure of the hydrogen ion concentration of the water as ranked on a scale of 1.0 to 14.0. The lower the pH of water, the more acidic it is. The higher the pH of water, the more basic, or alkaline, it is. pH affects many chemical and environmental processes in the water and different organisms have different ranges of pH within which they live and flourish.

The largest variety of aquatic creatures prefer a pH range between 6.5 to 8.0. pH outside of this range reduces the diversity in the water source because it stresses the physiological systems of most organisms and can reduce reproduction. A low pH level can also allow toxic elements and compounds such as heavy metals to become mobile and "available" for uptake by aquatic plants and animals.

The ARGES pH Sensor by Keynes Controls can accurately measure the pH in rivers, lakes and other water sources. Allow the sensor to settle to a steady-state value.

Measurement Integrity

All of the ARGEs sensor range have the serial numbers and the last calibration date stored internally. The user can access this information for reporting purposes. The sensors can be redeployed at any time with the calibration and serial number records are retained in the sensor.

Isolated Measurements

The sensor elements used in the pH Sensor are isolated when not to required for any measurements.

When no measurement is being made the sensor is in low power mode.

Additional Material:

Freshwater lakes, ponds and streams usually have a pH of 6-8 depending on the surrounding soil and bedrock ²¹. In deeper lakes where stratification (layering) occurs, the pH of water is generally higher (7.5-8.5) near the surface and lower (6.5-7.5) at greater depths.

The ARGES sensor covers the range shown above.

Product Features

| TYPE | RANGE (Typical levels) |

| Response | Fastest 1 Sec - Settling from dry 30 mins to be hydrated. |

| Measurement range: |

0 to 14 pH |

| Resolution: | 0.1 pH - 4 digits 2 decimal places |

| Accuracy: | +/- 0.02 pH - Typical |

| Temperature |

0-50 Deg C |

| Sensor re-calibration Period | 720 hours continuous use recommended. |

| pH Range | 0 - 14 |

| Operation | Solid state |

| Temperature Sensor | NTC 0 - 50 Deg C / 0.2 % accuracy |

| Sensor Type | Solid state reference - Glass Bulb pH |

| Built-in Digital Networks |

SDI12 / RS485 / MODBUS Digital Communications |

| Calibration Details | 2 Points using Calibration Standards. |

| Sensor Isolation | Reference cells isolated between measurements |

Calibration Summary

The Intelligent Submersible pH Sensor By Keynes Controls can be used within SONDE multi-parameter housing, or as a stand-alone sensor. The pH sensor should calibrated before use for optimum results.

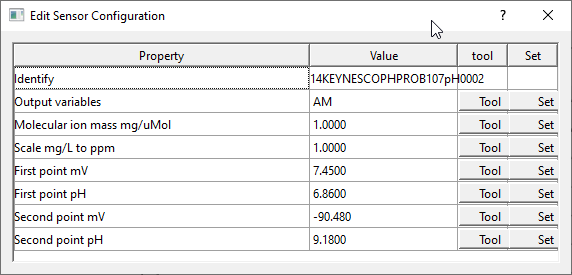

The ARGES pH Sensor by Keynes Controls is typically calibrated at 2 points. . The overall accuracy of the sensor will depend upon how well the ARGES pH sensor has calibrated. A high pH and low pH buffer solutions are ued to give the calibration points. pH measurements suffer little with temperature effects are the norm in water quality testing.

Like all glass cell pH sensors the instrument should be regularly calibrated. Use the standard calibration solutions. Make sure the sensor has been hydrated before use.

The ARGES pH Sensor by Keynes Controls user calibration Window in the Free QLOG software enables fast calibration and testing of the sensor.

Storage and Handling

When not in use the ARGES pH Sensor By Keynes Controls head should be kept hydrated with the protective cap attached.

Storage temperature range : 2 - 60 Degrees Celsius.

It is safe to store the sensor dry for a considerable time but the sensor must be re-hydrated before use.

Using Buffer Solutions

When calibrating the PH sensor, best practice is using buffer solutions that bracket the expected range. For example, if you want test water you expect to be in the 7-8 pH range, using buffer solutions for 6 and 9 pH is advisable.

Buffer solutions have limited shelf life, and their ability to maintain their pH in the face of contamination is limited. As such you shouldn’t reuse buffer solutions, especially not over a long period. Never return used solution to a stock bottle, this will contaminate the stock solution.

There are several internationally recognised pH scales, such as those developed by the United States’ NIST or United Kingdom’s BSI, but all are functionally interchangeable for practical purposes. While buffer solutions recognised by them do vary their pH with temperature, the effect is very limited.

Sodium Error

At very high pH levels (>11) the existence of other ions (most commonly sodium) can interfere with the detection of hydrogen ions and result in a substantially lower pH measurement than the actual value. For very high pH environments where accuracy is a concern, specialist equipment is advisable.

Product Specifications

| Network Type | ENVIRONMENTAL CHARACTERISTICS | |||

| SDI12 | 1.4 / Enhanced address supported. | Temperature Range: 0 to 60 Degree Celsius | ||

| RS485 | Ambient Range: 0 - 50 Degree Celsius | |||

| MODBUS | 16 and 32 Bit Registers | Water Temperature: 0 to 50 Degree Celsius | ||

| Maximum Depth: 50 m | ||||

| Process Electrodes: | Solid State Electrodes | |||

| Glass cell - Solid reference | PHYSICAL DIMENSIONS | |||

| Material | PVC / Stainless Steel | Length x Diameter: 22 x 220 mm | ||

| Weight: 97 g | ||||

| Settling Time |

|

Maximum Depth : 50 m | ||

| Return Parameters Order | User Defined | |||

| Built-in Network Types: | ||||

| Excitation | Galvanic | SDI12 V1.4/ RS485 / MODBUS over 485 | ||

| Housing | 316 Stainless Steel and PVC | |||

| Sensor Connector | Gold Plated | Power Requirement | ||

| SI Units | Automatically Defined | Voltage Range: 10-18 V DC | ||

| Data Output | ppm, mg/l, mol/dm³, Deg °C | Standby Current: 1 mA Typical | ||

| Temp Compensated | ppm, mg/l, mol/dm³ | Reading: 10 mA Typical |

Please Note: The pH sensors are pre-calibrated at the factory.

Supported Commands

The order for which the measurements are returned from the sensor can be user defined using the sensor configuration settings shown below. Use the free QLOG software to adjust the sensor setup and configuration.

Most Used Commands - SDI12

| Description | Command | Instrument Response |

| Start measurement | aM! | a05\r\n where 05 = time delay before measurement sent |

| Send ID | al! | a14KEYNESCOISO000014\r\n Part description assigned by Keynes |

| Address Query | ?! | Where a = ID number - 0 - 9 (standard) / (a..z) Enhanced SDI-12 0 - 9 / a - z for RS485 |

| Change Address | aAb! | where a = Initial address and b = Final address |

| Start Measurement | aM! | Make a measurement - a = address of sensor Example 1M! starts a measurement for sensor with ID=1 |

| Set Output Variables | XCSTR0 | Sets the parameter order for measurements sent from the sensor - factory set BCDM |

| Read Serial Number | aXSN! | Instrument Response a+Serial-number |

| Calibration Date | aXCD! | Instrument Response a+date |

| First Calibration point (pH) | XCA0 | Typical value = 6.86 |

| First point uncompensated (milli-Volt) | XCA1 | Typical Value = 7.45 |

| Second point (pH) | XCA2 | 9.18 pH - as read from the sensor |

| Second point uncompensated (mV) | XCA3 | -90.48 Conductivity from standard |

| Temperature Compen % per Degree C | XCA20 | Typical 0.03 % per/Degree C |

| First Calibration point (ppm) - | XCA0 | as read from the sensor - calibration mode |

| - | - | - |

| User Assigned Parameters | ||

| First Calibration point (ppm) | First calibration solution concentration in ppm | |

| First calibration point (millivolts) | Raw Sensor reading at 1st calibration point | |

| Second Calibration point (ppm) | Second calibration solution concentration in ppm - eg 100 ppm | |

| Second calibration point (mV) | Raw Sensor reading at 2nd calibration point | |

| SDI12 V1.14 Units | Automatically assigned - ppm, mg/l , mols/dm³ , Deg °C | |

| where mols/dm³ useful for high concentration readings | ||

| Calibration Temperature | Temperature in Deg C at which the calibration was undertaken | |

| Temperature Correction | millivolt / Deg C (-2.04 typically) |

Commonly used with: Typtophan, Turbidity, Dissolved Oxygen, Ammonia

The pH Sensor by Keynes Controls monitors the levels of pH in water. The ARGES pH Sensor by Keynes Controls readings can be affected by changes in temperature and salinity. This sensor is frequently paired with: pH, Turbidity, Tryptophan and Conductivity sensors and other temperature sensors crafted and produced by Keynes Controls.

Turbidity Sensor =The ARGES Turbidity sensor by Keynes Control is a single-channel instrument that can detect and report turbidity levels in the range of 0.5 - 1500 NTU. Read More...

Submersible Tryptophan sensor = The Intelligent Submersible ARGES Tryptophan Sensor by Keynes Controls, is a high performance submersible fluorometer that has been designed to detect the prescence of sewage levels in water souces as part of water quality measurement solution. This sensor is often combined with other instruments such as Ammonia, Dissolved Oxygen to monitotor the toxicity levels with the changes of pH increases, although less ammonia is required to produce toxic effects at lower pH.

Dissolved Oxygen

Oxygen is consumed as ammonia is oxidised (nitrification), and low oxygen levels increase ammonia levels by inhibiting nitrification. The ARGES Dissolved Oxygen sensor is used to monitor the oxygen levels in river water.

Built-in Communication Options

ALL of the ARGES range of chemical sensors support MODBUS network operations The sensors act as a slave unit only and can communicate to suitable controllers and SCADA systems that support the MODBUS Protocol. The sensors support 16 and 32 bit registers. .

The ARGES sensors can be connected to a PC based system using the optional USB-485-Pro media converter. This device can power the chemical sensor and supports the correct timing protocols for data transmission for MODBUS and standard RS485 network communications

The ARGES pH Sensor is integrated into the Keynes Controls free Q-LOG software.

Our Q-LOG software runs on the widely recognised Windows Operating system, and gives the user the ability to calibrate, adjust instrument network operations, and effortlessly display measurements on a series of panel meters and charts. Conveniently store results in text based files for quick analysis in spreadsheets.

Our highly chemical sensors provide chemical concentration and local temperature readings in SI units (Engineering units). Customise the SI units based on your instrument's capabilities, including support for multiple units like turbidity sensors, all easily managed through the device setup.