The Keynes Controls ARGES Conductivity sensor is a submersible instrument that can be used to measure Conductivity, Practical Salinity and Total Dissolved Solids. The sensor can operate as a stand-alone, and as network instrument and is offered with an optional USB interface. Measuresments are raw and temperature compensated. Conductivity measurements are corrected for 25 Deg C. The Practical Salinity and TDS calcaulations can be adjusted to suit different industry standard calculations. The sensor is preset for the most common options by default.

The sensor supports SDI12 v1.4, RS485 and MODBUS communications.

ISOLATION

The sensor element of the ARGES Conductivity sensor by Keynes Controls is isolated to prevent polarisation This prevents contamination of the sensor element and maintains the long active life of the device.

When no measurement is being made the sensor is in its lowest power mode.

The conductivity sensor is used in collaboration with the other water quality sensors for pollution monitoring. The conductivity sensor is often deployed with the Submersible pH Sensors, Submersible Chemical Sensors for Effluent Detection, Oil Pollution measurements, and Sewage sensor to as part of the water quality sensor system.

Measurement Integrity

All of the ARGEs sensor range have the serial numbers and the last calibration date stored internally. The user can access this information for reporting purposes. The sensors can be redeployed at any time with the calibration and serial number records are retained in the sensor.

Product Features

| TYPE | RANGE (Typical levels) |

| SDI12 . | 1.4 compliant - auto assign units.SDI12 v1.4 compatable |

| Measurement range: | 0-100,000 µS / 0 - 72000 mg/L (Practical salinity) / 0 - 58000 mg/L (TDS) |

| Resolution: | 0.05 µS 6 digits 2 decimal places |

| Accuracy: | ± 0.25% of full scale |

| Built-in Digital Networks |

SDI12 / RS485 / MODBUS (16 & 32 Bit Registers) |

| Sensor life: | Approximately 6 months, depending on usage. |

| pH Range | 2-12 |

| Isolated Electrodes | Cells are isolated between measurements to prevent degradation |

| Sensor Element | Solid state |

| Temperature Compensation | Automatic - correction to 25 Deg C 2%/Deg C (Adjutsable) |

| Conductivity | Raw Conductivity (Deg C) + Conductivity ( @ 25 Deg C) |

| Total Dissolved Solids (TDS) | 442 Conversion |

| Practical Salinity Scale & Offset Factors | PSS-78 standard based linear equation |

| Measurements | SI Units µS(micro-Siemens) TDS(mg/l), salinity ppt Deg-Celsius |

The ARGES Conductivity sensor

The ARGES Conductivity sensor by Keynes Controls can be used to determine:

- EC - Conductivity - micro-Siemens/cm

- EC - Temperature compensated - micro-Siemens/cm

- TDS - Total Dissolved Solids - SI Units ppm / mg/L

- Salinity - SI Units ppt parts per thousand

Operation

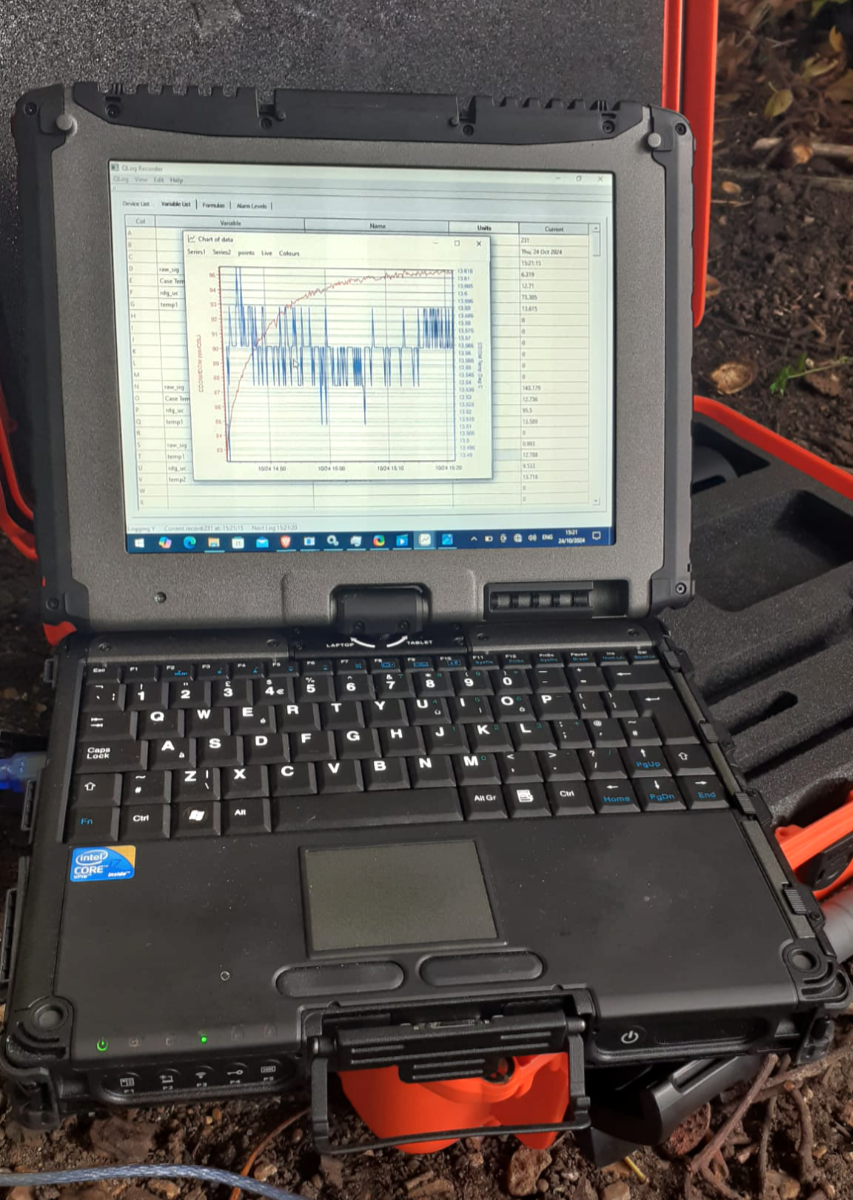

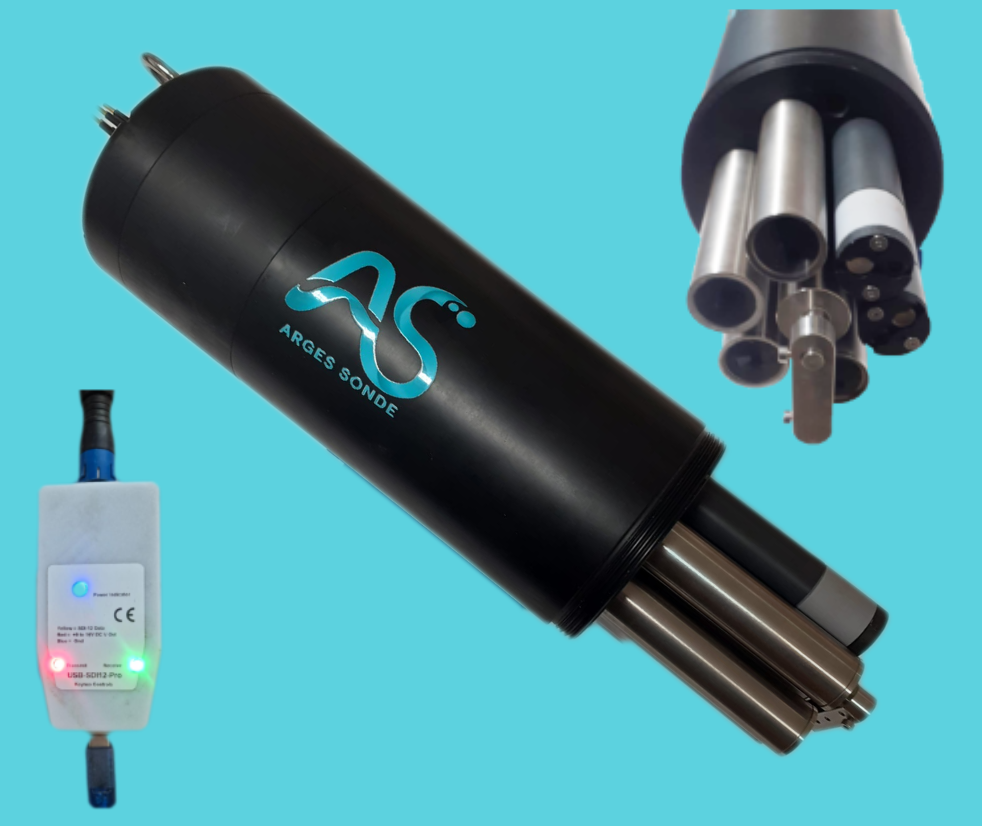

The ARGES Conductivity sensor can be used as a stand-alone device and as part of a multiparameter solution. The images opposite show the ARGES Conductivity sensor under test calibration and as part of a 3 sensor multiparameter system.

The optional USB-SDI12-AG1 is used to connect and power the sensor directly from a USB port on a Windows PC.

WATER CONDUCTIVITY RANGES (Typical levels)

| WATER TYPE | RANGE (Typical levels) | MEASUREMENT |

| De-ionized water: | 0.03 - 0.05 | μS/cm |

| Distilled water: | 1 - 5 | μS/cm |

| RO Permeate range: | 400 - 750 | μS/cm |

| Sea water: | 45 - 55 | mS/cm |

| Brine Rejection Range: | 90 - 95 | mS/cm |

Product Features

| CONDUCTIVITY SENSOR | |||

| Range | 0 - 100000 (mS/m) - milli-Siemens | ||

| Resolution | 0.1 μS/cm | Built-in Temperature Sensor | |

| Accuracy | ± 0.25% of full scale | Water Temperature: 0 to 60 °C | |

| Automatic Range Adjustment | Maximum Depth: 50 m - other ranges available | ||

| Process Electrodes: | Solid State Cells | ||

| Material: | PVC / Stainless Steel | PHYSICAL DIMENSIONS | |

| Fast Start Time | <0.5 Sec | Length x Diameter: 22 x 220 mm | |

| Isolated Sensor Elements | Between measurements | Weight: 97 g | |

| Settling Time |

10 sec | ||

| Conductivity | SI Units - µS/cm | Built-in Network Types: | |

| Temperature Sensor | NTC 0-50 DegC /0.2 % accuracy | SDI12 / RS485 / MODBUS Digital Communications | |

| Total Dissolved Solids | TDS using 442 Conversion | Power Requirement | |

| Simple Calibration | Offset Scale parameters | Voltage Range: 10-15 V DC | |

| Practical Salinity | PSS-78 standard linear equation | Standby Current: 0.8 mA Typical | |

| Free Windows Applications Software | Reading: 16 mA Typical |

Supported Commands

The order for which the measurements are returned from the sensor can be user defined using the sensor configuration settings shown below. Use the free QLOG software to adjust the sensor setup and configuration.

Most Used Commands - SDI12

| Description | Command | Instrument Response |

| Start measurement | aM! | a05\r\n where 05 = time delay before measurement sent |

| Send ID | al! | a14KEYNESCOISO000014\r\n Part description assigned by Keynes |

| Address Query | ?! | Where a = ID number - 0 - 9 (standard) / (a..z) Enhanced SDI-12 0 - 9 / a - z for RS485 |

| Change Address | aAb! | where a = Initial address and b = Final address |

| Start Measurement | aM! | Make a measurement - a = address of sensor Example 1M! starts a measurement for sensor with ID=1 |

| Set Output Variables | XCSTR0 | Sets the parameter order for measurements sent from the sensor - factory set BCDM |

| Read Serial Number | aXSN! | Instrument Response a+Serial-number |

| Calibration Date | aXCD! | Instrument Response a+date |

| First Calibration point electrical (K) - Conductivity | XCA0 | Typical value = 0 |

| First point uncompensated (A) | XCA1 | Typical Value = 0 |

| Second point electrical (K) - Conductivity reading in calibration mode from the sensor | XCA2 | 500 uS Typical - as read from the sensor |

| Second point uncompensated (A) | XCA3 | 12824 Conductivity from standard |

| Temperature Compensation % per Degree C | XCA20 | Typical 1.92 % per/Degree C compensated salinity correction for PSS-78 |

| Calibration temperature | XCA21 | Corrected to 25 Deg C |

| TDS k factor | XCA23 | Factory set 0.67 Typical range 0.5 - 0.8 |

| Practical Salinity Offset | XCA24 | Factory set = -3.7655 |

| Practical Salinity Scale Factor | XCA25 | Factory set = 0.7317 |

| AAA | ||

| BBB | ||

| SDI12 V1.14 (Default factory settings) | ||

| String ID = A | XVIDS0 | Conductivity level as directly measured by the sensor. |

| String ID = B | XVIDS1 | Temperature compensated Conductivity μS/cm at 25 Deg C |

| String ID = C | XVIDS2 | Total Dissolved Solids |

| String ID = D | XVIDS3 | Practical Salinity |

Sensor Settling Time

The sensor has a fast response time once deployed into a new water sample. For relatively low conductivity readings the sensor takes only a few minutes reach its steady level results. In practice allow up to 1 hour for the sensor to settle before long time measurements are taken.

For high level conductivity measurements such as when used to monitor brine, allow up to 2 hours for the sensor to settle before taking long term measurements. Take the above sensor settling times as approximate only.

Calibration Period

The ARGES Conductivity sensor by Keynes Controls should be test calibrated at regular periods within 6 months . This operation is simple to undertake using the calibration solution, a beaker and the applications software.

Calibration Soultion

Calibration Solution Point: 1800 S KCl 3000 ppm 442 (2027 ppm NaCl)

0.01 Molar 0.74555 g/L 1408 μS/cm

0.1 Molar 7.4555 g/L 12824 μS/cm

1.0 Molar 74,555 g/L 108620 μS/cm

Calibration solutions available from the online shop

Storage and Handling

When not in use the ARGES Conductivity sensor head should cleaned before deplaoyment in distilled water. The sensor is safe to store dry for long periods of time.

Storage temperature range : 2 - 60 Degrees Celsius.

Engineering Results - SI - Automatically Set

The Conductivity, Practical Salinity and TDS (Total Dissolved Solids) results are based upon the measurement of Conductivity. The Salinity and TDS calibration factors can be user assigned allowing the instrument to be used with various international standards. The factory set parameters are those commonly used with this sensor. Any new calibration factors can be assigned by the user stored directly into the sensor.

The ARGES Conductivity sensor can use the 442 Standard for TDS calculations

Uncompensated (raw) and Compensated Conductivity (@25 Deg C) are available from the sensor.

Practical salinity (PPT) uses the PSS-78 standard linear equation.

Built-in Communication Options

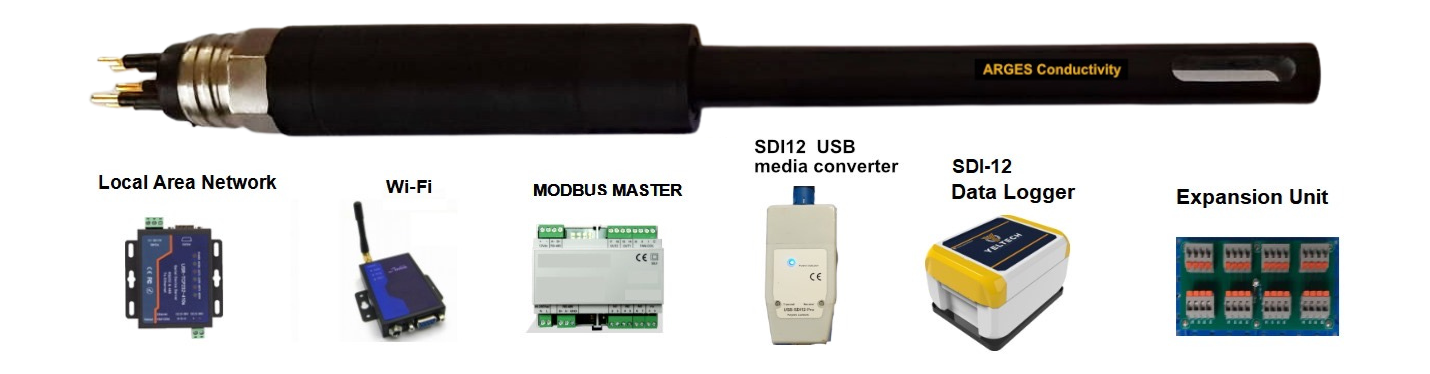

The ARGES Conductivity sensor by Keynes Controls supports SDI-12, RS485 and MODBUS digital communications as standard enabling the it to be directly connected to Data Logger for remote web based reporting, onto Wi-Fi and Local Area Networks using the RS485 option. The MODBUS and RS485 option are often used to connect sensors to a PLC Controller and Display Units.

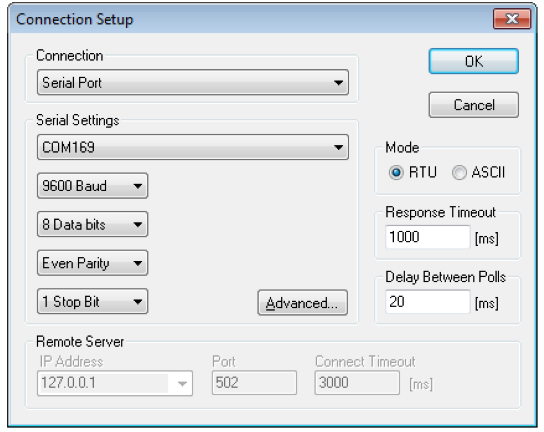

MODBUS Settings

ALL of the ARGES range of chemical sensors support MODBUS network operations The sensors act as a slave unit only and can communicate to suitable controllers and SCADA systems that support the MODBUS Protocol. The sensors support 16 and 32 bit registers. .

The ARGES sensors can be connected to a PC based system using the optional USB-485-Pro media converter. This device can power the chemical sensor and supports the correct timing protocols for data transmission for MODBUS and standard RS485 network communications

Keynes Controls manufactures a range of accessories that can be used to connect the ARGES range of sensors. Multiport housings can support any combination of sensor.

The optional USB media converter can be used to connect The Intelligent Submersible ARGES Conductivity Sensor by Keynes Controls, or a multiparameter systerm to a Windows PC.

The ARGES Conductivity sensor by Keynes Controls is integrated into the free Q-LOG Applications software. The software enables the sensors to be fully configured and report real-time measures directly to a Windows PC.

Our Q-LOG software runs on the widely recognised Windows Operating system, you have the ability to calibrate, adjust instrument network address, and effortlessly display measurements on a series of panel meters and charts. Conveniently store results in text based files for quick analysis in spreadsheets.

WARNING:

Favourable measurements made by this equipment do not guarantee that a water sample is safe for human or animal consumption. The ARGES sensors can not detect the presence of harmful bacteria or toxins. If in doubt, ALWAYS TREAT SUSPECT WATER PRIOR TO CONSUMPTION.